The Non-Destructive Testing Group offers a complete range of inspection services, both in the field and in the laboratory.

These services include NDT, Quality Control, Quality Assurance and Mechanical Integrity.

The group’s capabilities include a wide range of testing methods such as Ultrasonic, Radiography, Magnetic Particle Testing, Liquid Penetrant, Eddy Current & Positive Material Identification with certifications in accordance with SNT-TC1A.

Our technicians are certified API 653/510/570 Inspectors and Certified Welding Inspectors. We serve various industries such as Automotive, Utility, Civil, Department of Transportation, Medical, Electronics, Casting and Forging, Light/Heavy Manufacturing, Bridge/Building, Aircraft and more.

Our services include a weld testing facility that includes machine tools and bend testers to assess and approve the skills of your welders. Our testing turnaround is swift and accurate at an affordable price.

Our Laboratory Services

-

X-ray Services

At our location, we have two x-ray machines in use at our facility. This COMET 450 KV model, and the other COMET 225KV with a real-time digital detector. We perform digital Capture, Computed Radiography and traditional film RT.

-

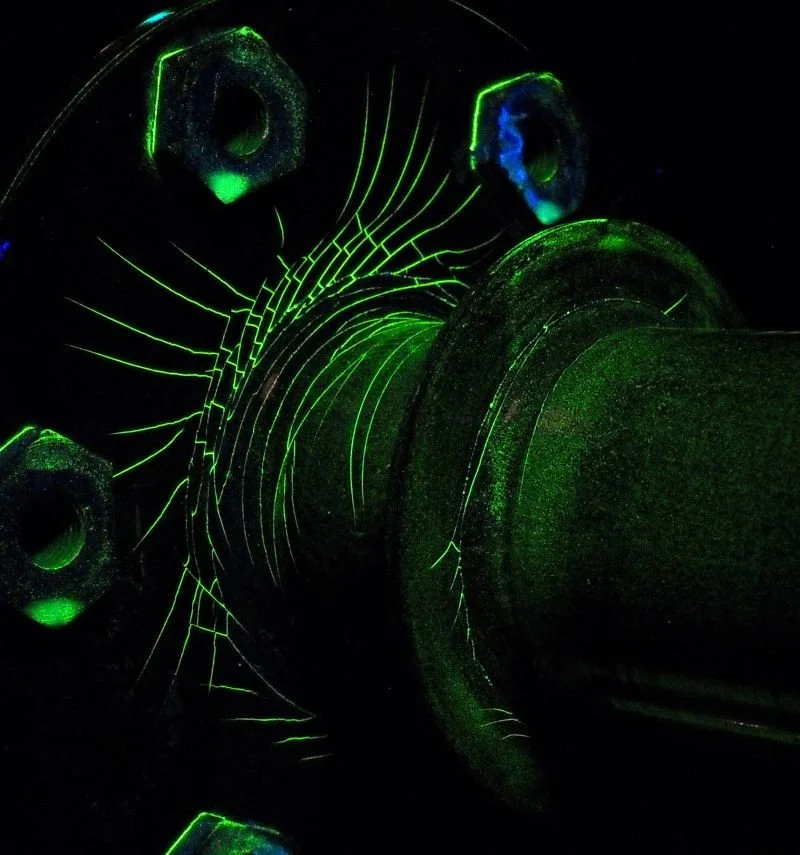

Magnetic Particle Testing

Our machines have the capacity to handle larger parts, either castings or machined. Large orders or small can be processed quickly with same day reporting.

-

Liquid Penetrant Line

LPT is a widely used and cost-effective method for detecting surface flaws and discontinuities in materials. It is commonly used in industries such as aerospace, automotive, and manufacturing to ensure the quality and integrity of critical components.

-

Weld Test Shop

Our Certified Welding Inspectors are experts in procedure writing and review, testing the process including the cutting and bending of test samples. We also provide Charpy and Tensile testing.

-

Material Sorting

Whether it is a material issue or defects that make a part non-conforming, we can help. Our experts have been sorting parts, and insuring only the conforming parts pass for years. This work can be performed in-house and at your location.

-

Hardness Testing

As with our other in-house services, Hardness Testing can be bundled with other NDT to provide a one-stop for your needs. We also have field worthy units to use at your location.

Field Inspection Services

-

API Inspection Services

The API 653 inspection covers various aspects of the tank, including its shell, roof, foundation, nozzles, and appurtenances. The inspection also includes non-destructive testing (NDT) to detect any defects or anomalies in the tank material. Based on the inspection findings, the inspector may recommend repairs, alterations, or other corrective actions to ensure that the tank remains safe and reliable.

-

Certified Welding Inspectors

Certified Welding Inspectors play a critical role in ensuring the safety and quality of welded products and structures. They work closely with welders, engineers, and quality control personnel to ensure that welding processes are performed correctly and that the resulting welds meet the required standards for strength, durability, and reliability.

-

Advanced and Conventional NDT

Phased Array Ultrasonics

Eddy Current Testing

LiDAR Surveys

Hardness Testing

Positive Material Identification